Richard Clinnick witnesses the arrival of the first Class 93 and provides all there is to know about the new tri-mode locomotive.

The first tri-mode Class 93, No. 93001, arrived at Worksop on July 1, where it will be based for the next few weeks before beginning a period of maintenance and main line testing.

It is the first of an initial batch of 10 locomotives owned by Rail Operations Assets Ltd (ROAL) that are being built by Stadler in Valencia, Spain. Factory testing has already been undertaken at the Spanish facility; however it cannot yet run on its own power on the national network here in the UK. Instead, testing using an unbranded No. 93002 is underway at the Faurei test facility in Romania. There, the locomotive will undergo various tests which will enable the class to receive the various certification required from the UK regulator, the Office of Rail and Road (ORR) to operate on Network Rail infrastructure.

Enjoy more Rail Express Magazine reading every month.

Click here to subscribe & save.

No. 93001 arrived by ship at Portbury Docks, Bristol, on June 28. It was unloaded the same day and after the various checks were completed, it left that site on June 30, by road, arriving at the Harry Needle Railroad Company (HNRC) facility around lunchtime on July 1.

Rail Operations Assets Ltd is part of the Rail Operations (UK) Ltd group, sitting alongside Rail Operations Group (ROG) and was created last October. In the family tree, ROG sits alongside Orion (the logistics business) and Traxion (a rolling stock storage business). Although the ‘93’ carries the new ROG livery and branding, it is not planned to haul just trains for that company. Instead, the plan is for the ‘93s’ to be made available to other operators.

But what is a Class 93? The locomotive, part of the Stadler EuroDual platform, is an RA7, 110mph Bo-Bo tri-mode locomotive that features electric, diesel and battery traction. They weigh 86 tonnes, have a 73t brake force and are 67.6ft long (over buffers, 69.6ft over the automatic coupler). They were ordered in January 2021, two days after STAR Capital Partnership acquired a majority stake in ROUK. This provided significant growth capital, enabling the signing of a framework agreement for the ‘93s’, which are the first tri-mode locomotives built by the Swiss manufacturer.

The ‘93’ is equipped with four AC induction traction motors and is capable of providing a nominal electric power of 4MW via the overhead wires (5400hp), which increases to 4.6MW via ‘Boost’ mode (6168hp).

The locomotive offers 900kW (1200hp) on its diesel engine and 400kW (536hp) via its two 200kW battery traction packs. There is a diesel and battery hybrid mode which offers a combined 1300kW (1700hp).

Each Class 93 is fitted with a Stage V, 900 kW, C32 Caterpillar engine. The C32 is a 12-cylinder turbocharged, four-stroke engine with a mechanical electric unit injection (MEUI). It is rated at 900kW at 1800rpm. The fuel tank fitted to the Class 93 holds 3600 litres.

Regarding fuel efficiency, Rail Operations Assets Ltd says that when idling at 600rpm, the ‘93’ will consume 10 litres per hour. At Notch 4, it will operate at 1450rpm and consume 111 litres per hour, while at 1800rpm (Notch 8) it will consume 225 litres per hour. However, these fuel consumption figures are approximations with a 35kW simulated auxiliary load.

The battery traction packs are an energy storage system (ESS) that comprises two Lithium Titanate Oxide (LTO) traction battery packages. These battery packs can be charged via the overhead line catenary or from the diesel engine. When operating in ESS mode, the power is provided as follows: power from the batteries goes to the DC-DC converter, where the voltage is increased. The output current feeds into the DC link and current from the link is then inverted back to alternating current by traction and auxiliary inverters, ready for receipt by the traction motors and auxiliary components respectively.

As for the traction motors, each locomotive axle is fitted with an ABB asynchronous three-phase motor. These motors are force ventilated and are controlled individually through four separate traction inverters. When operated at a constant load the motor has a rated power of 1050 kW (1408hp)/1281rpm.

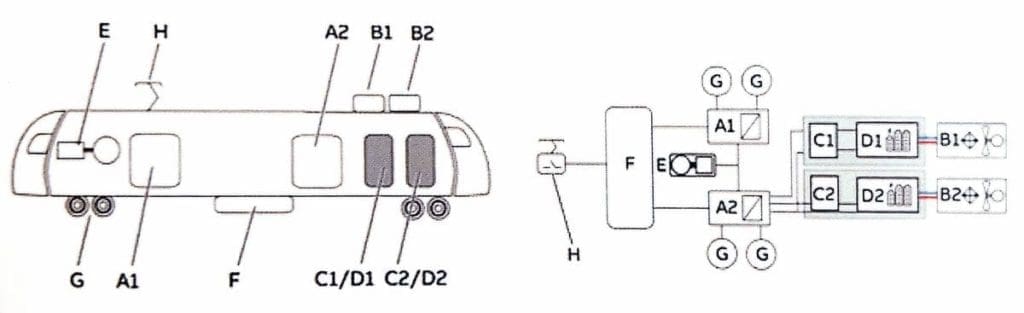

| A1/A2 | Compact converter |

| B1/B2 | Battery thermal management system |

| C1/C2 | Energy Storage System (ESS) filter |

| D1/D2 | Energy Storage System |

| E | Diesel generator unit |

| F | Transformer |

| G | Drive motors |

| H | Current collector with main circuit breaker |

Each Class 93 is fitted with a Siemens (Flender) AS5E48195589 gearbox with a gear ratio of 1:4087. They have a 250-metre curve radius at operating speed, which tightens to 150m at low speed in sidings or depots, and even reaches 80m at low speed as a single light locomotive.

The Class 93s also feature regenerative braking. When operating using overhead line electrification (OLE), the electro dynamic braking system will be regenerative and power will be transferred back to the OLE whilst the locomotive is braking. If the locomotive is operating either in diesel or hybrid mode, then the power from the regenerative braking will be used to satisfy the demands of the auxiliary loads and electric train supply (ETS), or will charge the battery packs.

The Class 93 also features various coupling systems, hence making it attractive to various users on Britain’s railway network. The locomotives are fitted with a hybrid coupler, a Voith Type 136 Automatic/Screw Coupler. The coupler has two coupling types. These are a Voith Type 136 when inthe lowered position, allowing coupling to a type 10 or type 12 coupler, and a UIC (International Union of Railways) screw coupler when in the raised position.

The adjustment between the two positions is undertaken via an electric winch which is controlled through a switch located on the driver’s desk and via a local control box.

Rail Operations Assets Ltd state that the coupler can be positioned at three different heights, which are 1025mm, 975mm and 925mm. The UIC shackle can only be used at 1025mm.

Class 93s are equipped with a single-phase AC, 900V 50 Hz ETS. The supply index is 96, which is the same as a Class 73/9 or ‘88’ and just under the 100 index for a Class 57. The ETS fitted to a Class 93 is able to provide 350kW continuously and 500kW for one hour.

The locomotives are also fitted with the STAV Telemetry System. This allows for data to be transmitted wirelessly straight from the ‘93’ to a remote server for download and review. The data transmitted can be selected and can include the locomotive’s geographic location and fault messages and/or alerts.

Class 93 deliveries

Inside the cab, the Class 93s are fitted with a Driver’s Display Unit (DDU). On these, the driver can see an array of operational information including power/brake effort, selected notch, fuel level, current fuel consumption and error messages. The displayed information is able to be tailored as required. The screen also has a maintenance mode where it is able to display information on different locomotive systems, the engine and information to assist with fault diagnostics.

Multiple CCTV cameras are installed on the ‘93s’ including forward facing cameras in each cab, a shunting camera located above the coupling equipment, bodyside cameras (located low near the doors) and one for the pantograph.

Both the pantograph and forward-facing cameras are recorded within the CCTV system and can be downloaded manually or remotely. The other cameras can all be viewed via the DDU in each cab. The driver’s viewing options can be tailored as required.

ROG engineering director Richard Martin met Rail Express at Worksop on July 1, to welcome the ‘93’ to its current base. A long-term home for the locomotives has not yet been found, echoing the comments from ROG chief executive officer Dave Burley in an interview in RE323, when he confirmed that a maintenance facility had not yet bee decided on.

ROG is leasing two roads in a rebuilt former wagon repair shed at Worksop until the end of April 2024. This will allow the locomotives to be inspected and commissioned. Currently only No. 93001 is there and Richard said that it should be joined by Nos. 93003/004 in the first week of September. He said that the plan, as this issue of Rail Express went to press, was for two ‘93s’ to be delivered to the country every fortnight until at least the first 10 have been delivered.

Decisions regarding their onward movement from Portbury to Worksop have not yet been made, but moving them by rail has not been ruled out once certification has been received. They would be hauled by a ROG ‘37’, or even a ‘93’ already accepted.

Richard said that No. 93002 is due to stay in Romania until the middle of August when its testing is expected to be completed. After that it will return to Valencia where it will spend four weeks before arriving at Worksop in mid-October.

As is the case with No. 93001, when the locomotives arrive in Britain, they remain Stadler assets. They must each complete 1000 miles fault-free running before they are accepted. Plans are already in place for various organisations including regulatory bodies, operators, and other railway stakeholders to visit the first locomotive before it is able to venture out. Richard said that work is also underway to understand the maintenance requirements, with training of staff set to start imminently.

He also revealed that in order for the locomotive to undertake some running ahead of the certification process being complete, options were being explored to move No. 93001 to the Great Central Railway (GCR) where, under controlled possessions, it could operate at speeds of up to 75mph. The thinking here is that drivers can also continue to learn about the locomotive while components are kept moving. There is a shore supply at Worksop that will enable the ‘93’ to be powered up. Stadler are also sending a test team to Britain to assist with the training and testing of the new locomotive.

Once certification is received, the ‘93’ will move to Crewe, where it will initially be based. There had been potential plans to undertake testing at the Network Rail Rail Innovation & Development Centre (RIDC) at Old Dalby, however this may no longer be required.

Main Line testing

Initial testing will be conducted between Carlisle and Crewe, and this will seek to compare and validate data with other Stadler fleets which share a lot of commonalities with the ‘93s’. Richard said that ROG and Direct Rail Services have been talking about maintenance being undertaken at Crewe Gresty Bridge during this period. ROG is arranging its own trailing load for the new locomotive, and this will use Mk.3s potentially supplied by Eastern Rail Services. These locomotive-hauled coaches are able to operate at 110mph if required and will do so as part of the testing on the West Coast Main Line (WCML).

Much of the initial testing will be about validating the data received from the testing of No. 93002 in Romania. Incremental speed and braking tests need to be conducted. Testing will initially be using empty coaching stock before loads are added to the coaches. It is expected that initial test running will head north from Crewe, but Richard says that Network Rail has provided paths to operate between Carlisle and London Euston, although he says that realistically the ‘93’ will run as far south as Bletchley. Testing with Mk.4s, and a number of other vehicles, is also planned, he said.

Once they are accepted, what will the ‘93s’ do? It is doubtful that they will be seen hauling redundant stock to scrapyards, or to storage facilities, according to Dave when he spoke to RE in February (RE323), and Richard confirms that remains the case before adding that under the current plans, while Nos. 93001-005 will be delivered in the new green ROG livery, there are no plans to apply that scheme to Nos. 93006-010, leaving options open for operators.

He explains the situation regarding Worksop and the future. “Officially, this is the home for the locomotives until April 2024, but we are looking at several sites. A home depot also depends on the lease arrangement and whether it is a ‘dry’ lease or a ‘wet’ lease. The likelihood is that a lessee will undertake the smaller A, B and C exams but anything bigger we would undertake. The locomotives can also be branded in their livery.” This is a similar option to the way in which Chiltern Railways uses Class 68s hired from DRS.

As for where they could be used, Richard says of the ‘93s’: “They are equally suited for freight traffic and passenger services. They could haul TransPennine Express’ Mk.5As without a problem and a number of passenger operators have enquired about the locomotives.” He says that one potential operator could look to use them on the East Coast Main Line, but he says he’s unable to confirm which operators are looking at the locomotives, although he doesn’t rule out an announcement in the coming weeks.

Future options

“It became clear from conversations that the tri-mode option is appealing. In the freight sector there are operators using electric traction but they have to swap traction for ‘66s’, or use ‘66s’ for complete journeys under the wires. This can eliminate that.”

Recent government figures revealed that only 11% of all rail freight is hauled by electric traction. The ‘93’ is viewed as a predominantly electric locomotive, but its hybrid traction can enable it to operate away from the wires (on the Felixstowe branch, for instance) and keep to time.

“What an ‘88’ does, a ‘93’ will do.” He suggests that the various modes would make the ‘93’ attractive for operators who run trains under the wires but have to enter non-electrified terminals.Currently ten locomotives are on order, but there are options for further batches. These orders must be exercised within a pre-agreed contractual framework.

Richard explains that the first batch of 10 could be constructed as a ‘follow-on’ order from the first batch, and so would be delivered in around 24 months, however due to the need to source the material and fit in a build slot at Valencia, additional batches could be up to three years away, dependent upon the structure of deals and acquisition of the necessary material. Discussions are ongoing.

The ‘93’ is the next step in the continued growth of ROUK, which started as an innovative company a decade ago, and has now reached the stage of taking delivery of a brand-new environmentally friendly locomotive that could help the railway meets its decarbonisation targets. It’s a project to watch.

Class 93 Specifications

Numbers: 93001-93010

Owner: Rail Operations Assets Ltd

Built: 2022-2023, Stadler, Valencia

Maximum speed: 110mph

Tractive effort: 290kN (starting)

Continuous tractive effort: 229Kn

Class 93 Operating Modes

| Operating mode | Power output |

| Electric AC mode | 4MV |

| Diesel | 900 kW |

| Battery traction packs | 2×200 kW |

| Hybrid (diesel/battery) | 900 kW+400 kW |

| Boost mode* | 4.6MW |