Trials are underway using a battery-powered Class 08. Richard Clinnick attended the launch of the locomotive at Barrow Hill.

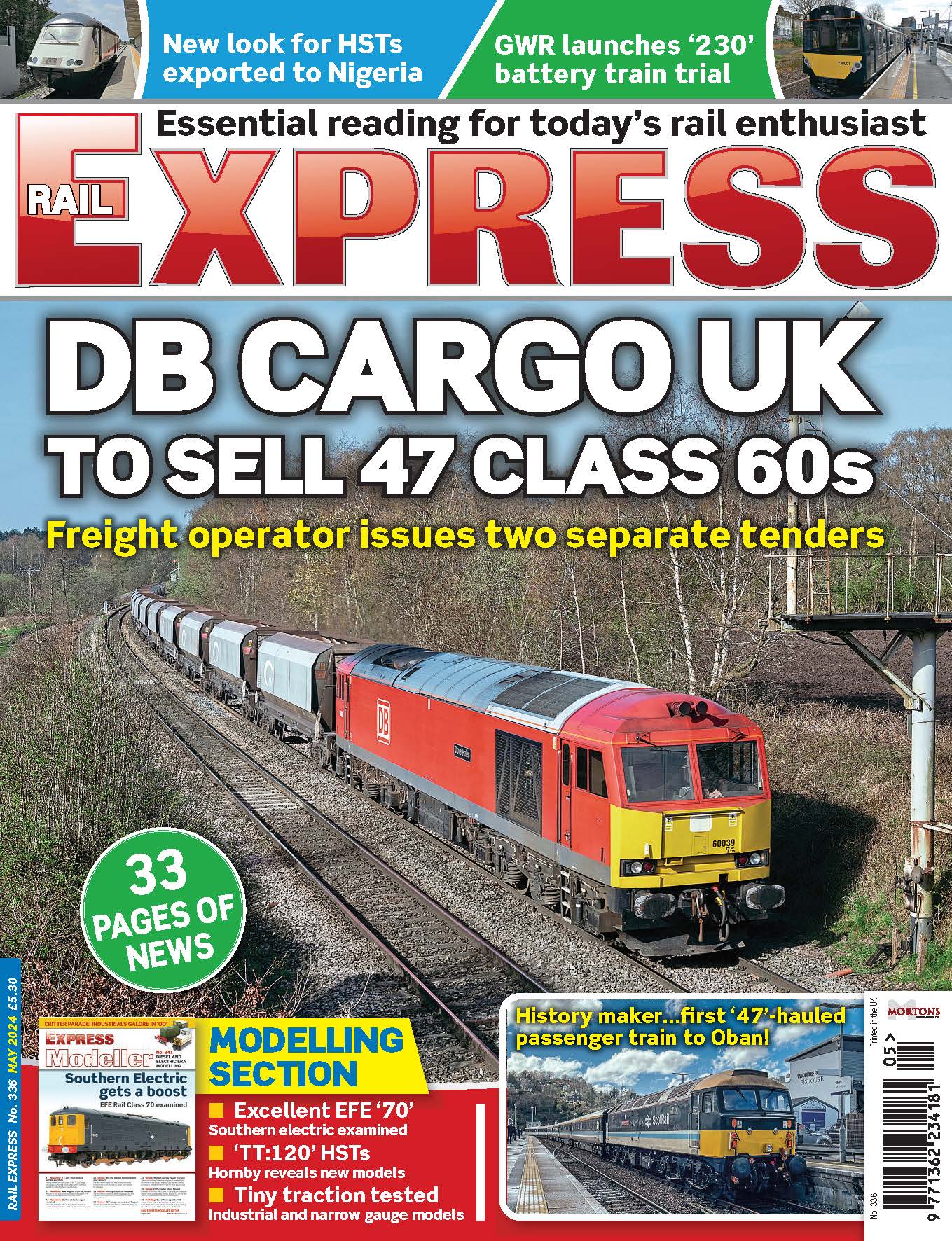

There is something vaguely familiar about No. 08308 as it moves almost silently from the turntable in the Barrow Hill Roundhouse on October 19. Yet this locomotive is very different from the one delivered to Royston as No. D3378 in August 1957.

It’s a lot quieter for a start, and there are no emissions. The familiar bonnet has been removed, while the cab has been significantly upgraded with more windows fitted. However, it does still retain a bonnet (albeit a different shape). And, beneath the solebar at least, it retains its original equipment. However, the modifications above the solebar could enable the humble Class 08 to remain in traffic for even longer than anticipated.

Enjoy more Rail Express Magazine reading every month.

Click here to subscribe & save.

The locomotive is the prototype for the ‘08e’ project, which replaces the English Electric 6KT engine fitted to the locomotive with a PT Powerpod, while controls are provided by the PT Powertrain system.

The first Class 08, No. D3000, was delivered new to Tyseley in October 1952. Now, 71 years later, the class remains in traffic across the country, however Positive Traction (PT), an engineering company based in Chesterfield, has created a prototype it believes can offer a solution that should prove attractive to companies still requiring shunting locomotives.

The need for more than 1000 shunting locomotives, as was built in the 1950s and 1960s, has vanished, however there are still 170 Class 08s and 11 Class 09s in various conditions across the length and breadth of Britain, owned by companies either hiring or operating shunting locomotives. The operational examples can still be found pottering around depots and terminals and they have even started reappearing in locations where their existence had been deemed redundant (Peterborough) or even breaking new ground (Great Yarmouth).

However, as expected for technology dating from the 1950s (and earlier), their place on the 21st century railway is seemingly limited as the industry seeks to meet various Net Zero targets.

Morri Consultant’s Paul Riley, who worked on the conversion of No. 08308, tells Rail Express at Barrow Hill on October 19, that the locomotive features no diesel, which means there are no emissions and no particulates. As railway land around active sites is increasingly being sold and built on, this is important he says, because it shows the railway can remain a good neighbour.

Various alternative forms of traction have been trialled in recent times, yet the ‘08’ seemingly remains first choice for customers. They are used on a wide variety of duties from shunting wagons and moving multiple units, to shunting heavy freight trains ready for collection for main line traction.

PT’s design, based on engineering expertise, renewable energy knowledge and its industry network to develop the design, using No. 08308 as a donor, has created a shunting locomotive free from carbon, NOx and particulate emissions, yet which can fulfil the day-to-day operating needs as well as meet the demanding Environmental, Social and Governance (ESG) requirement from shareholders, customers, employees and neighbouring communities.

Why use No. 08308? A varied career saw the ‘08’ end up at Inverness on hire to Caledonian Sleeper, however it was removed from service as it required new pistons and a crankshaft and was stored at RMS’ Wolsingham facility.

Modified

The ‘08e’ remains a Class 08. However, it is heavily-modified and is fitted with modern ‘plug-in’ traction batteries and control equipment – the PT Powerpod and PT Powertrain. The former contains battery cells, a battery management system and a battery charger. Up to six Lithium-Ferro-Phosphate (LFP) 88kWh battery pods can be fitted to the locomotive.

Meanwhile, the PT Powertrain acts as the control centre. It manages the traction control, battery status, monitoring, driver interface, diagnostics and data control which PT says is essential for the conversion.

The design is fully scalable with a range of battery configurations that are designed to meet the most demanding duty-cycles and power requirements.

The cab modifications deliver all-round visibility while retaining the familiar Class 08 control desk. This reduces the driver and depot staff training time and, in theory at least, means a driver trained on ‘traditional’ Class 08s can drive the modified locomotives.

There are cab enhancements including double-glazing, remote monitoring equipment and a roof-mounted heating, ventilation and air-conditioning (HVAC) unit.

Standard BMAC head/tail-light clusters are fitted to No. 08308. The ‘08e’ also features regenerative braking, internal and external CCTV, new oil-free connecting rod bearings to reduce maintenance and prevent oil loss onto interior floors. Ethernet connections support remote diagnostics, multiple working and remote control.

The ‘08e’ has also been designed for ease of maintenance, with the frames retained from the original design, as are the traction motors which, along with the bufferbeams can be maintained at ground level. Doors around three sides of the bonnet allow changes to battery and control equipment modules with a forklift truck.

PT says that the ‘08e’ prototype is rated at around 450hp and that its tractive effort has been increased from 35,000lbf to 45,000lbf (200kN), which is the equivalent of a Class 33.

Alistair Gregory, PT director said: “Class 08 shunting locomotives have been the workhorses of ports, distribution centres and depots across Britain’s railway for over 60 years. As the UK moves towards Net Zero, diesel engines are increasingly unacceptable. To address this challenge, Positive Traction has developed the ‘08e’, a cost-effective battery powered alternative for environmentally friendly facility operations.

“I’d like to thank all our partners for supporting our cleaner, greener UK transport vision, including Lithion Battery Inc; Barrow Hill Limited; Stagecoach Yorkshire and their own partners Volvo, who kindly supplied the very latest electric Volvo BXL bus to bring our guests from Chesterfield station to Barrow Hill in a sustainable way.”

Speaking at the event onOctober 19, Mr Gregory said: “This design will keep our business lasting longer. Our sister company RMS Locotec has 20 Class 08s in service, and it is not sustainable to keep them going for another 10 years. We looked at the solutions and decided to do it ourselves because there was nothing on the market.”

Rebuild

Mr Riley, who has worked on various rail projects for Fragonset Railways and Rail Vehicle Engineering Limited amongst others, explains that while initial testing is being conducted at Barrow Hill, the actual rebuild was carried out at Independent Rail’s facility at nearby Chesterfield. This is situated adjacent to a bus garage and has been used for several rail projects in recent months for a variety of customers, including major rebuilds and conversions. The ‘08e’ is no exception. “We have removed the diesel generator and ancillary equipment and replaced it with batteries.” These were removed prior to the locomotive leaving Wolsingham for Chesterfield.

Upon arrival it was further stripped down with the fuel tank drained and removed, all the air receivers were also removed and sent for inspection and overhaul while all the window glass and redundant electrical wiring was removed.

Once No. 08308 was stripped it required significant preparatory work, having been stored for several years. The ‘08’ was needle-gunned and all signs of corrosion were repaired before a fresh coat of primer was applied. By this point the familiar bonnet had also been removed ready for the new design.

At this point PT could consider rebuilding the shunter. Layers of interlocking platers were first to be considered as these would replace the weight lost from the removal of the obsolete components. These metal plates can be adjusted as required depending on the application required.

Old rod bearings were replaced with self-lubricating composite versions, which Mr Riley says is an example of how prior issues discovered on ‘08s’ are also being removed (the shunters are known for dripping oil from their rod bearings).

“We are aiming at 1.5 times the power of an original ‘08’,” says Mr. Riley. “The size of the motors is the issue. The originals were over specified but now we can put more current through them. The ‘08e’ has not been designed with any specific job in mind.

“It is modular, so customers can add battery pods as required. Currently there is one fitted to No.08308, but there can be up to six.” He says that trials will examine the capability of various numbers of pods. “The charge required will depend upon the duty cycle of the locomotive. It will regenerate power automatically, but we think that if it was shunting coaches at Derby then a couple of pods would be required, and it could go a couple of days between charges.”

As for where it will go after, a PD Ports site is likely, although Mr Riley didn’t specify which. The locomotive is also a PT asset having been acquired from RMS, he says.

Bonnet

“There’s always good ideas in the railway but people need to see something tangible. There is nothing out there like this. Class 08s are incredibly hard to get components for and they need TLC [tender loving care].”

The new bonnet design is designed to contain the battery pods, control system, auxiliary converter, air dryer and air compressor. However, it is lower than the original and this significantly enhances visibility from the locomotive’s cab, therefore improving safety for the driver and those nearby says PT.

Mr Riley suggests that while the ‘08e’ is the prototype, as the railway looks to decarbonise, so other locomotive types could be modified. He suggests Class 20s, ‘37s’ and even ‘66s’ could be ripe for such work. Should No. 08308 prove a success then a production line of ‘08e’ locomotives could be up and running next year he says. The most time-consuming aspect of the project was stripping the locomotive, he added, highlighting that because the design is modular it can be put together very quickly. Both he and Mr Gregory confirm to RE that other companies have expressed interest in using ‘08e’ locomotives, and the day at Barrow Hill was attended by representatives of various users including freight operating companies, terminals and ports.

Mr Riley admits that Chesterfield would be too small for a production line of ‘08s’ and says other possible sites have been identified for the work should contracts be awarded, however he stopped short of saying where these were.

No. 08308’s testing will be fascinating to keep an eye on, and could mean that, while the railway continues its drive towards Net Zero, a design first introduced in the early-1950s, could play a vital role in the new, modern railway.